Parts washers catalog ROBUR LINE

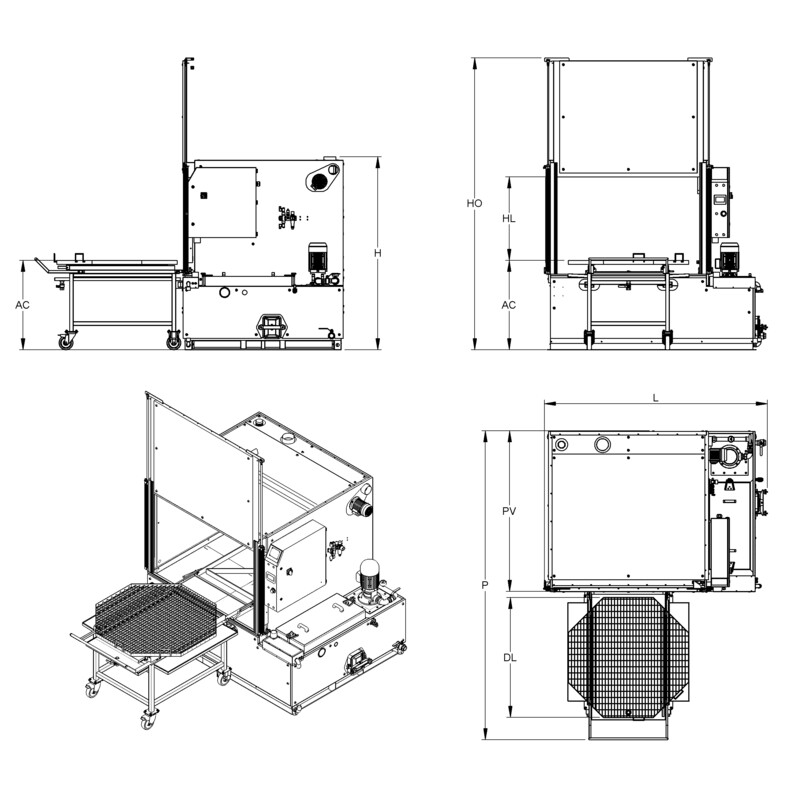

| Washing capacity ( Ø x H ) | Basket load capacity | Tank | |

| R 1000 | Ø 90 x H 70 cm | 600 Kg | 450 lt |

|---|---|---|---|

| R 1200 | Ø 110 x H 80 cm | 600 Kg | 550 lt |

| R 1400 | Ø 128 x H 90 cm | 600 Kg | 750 lt |

| R 1800 | Ø 165 x H 100 cm | 800 Kg | 1000 lt |

| R 2200 | Ø 200 x H 100 cm | 800 Kg | 1200 lt |

| R 2600 | Ø 225 x H 100 cm | 800 Kg | 1200 lt |

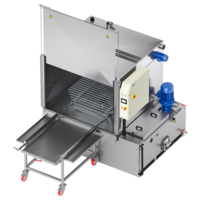

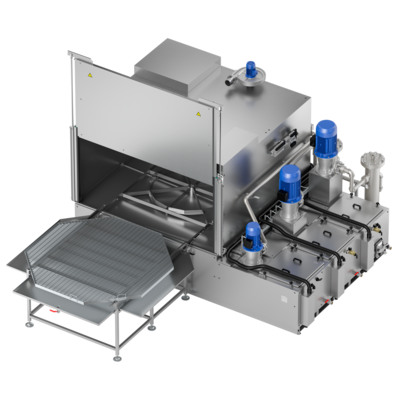

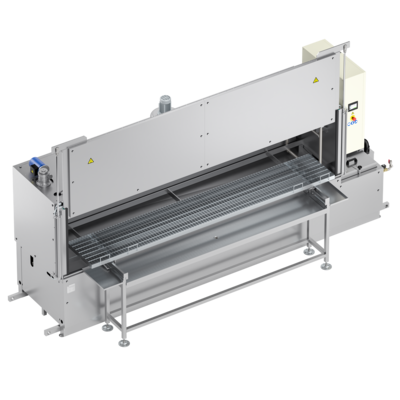

Rotating basket metal parts washer for very large volume and heavy parts

Robur performs the successful automatic washing of medium and large size mechanical parts.

Washing is carried out by the action of upper, lower and side nozzles. The slow rotation of the platform is ensured by a gear motor with a torque limiter.

A PLC management enables numberless customisations thanks to a wide range of accessories. The high-capacity tank is separate from the washing chamber and it is mounted on the right side of the machine.

- LT (heating up to 60° C)

- HT (heating up to 80° C)

- PLC with color Touch Screen

- Industry 4.0 option

- Unique tank

- Truck maintenance

- Railway, naval, aeronautical maintenance

- Mould washing

- Mechanical engineering, chip removal, foundries, moulding

- Surface treatment, pre-painting, paint stripping

- Aeronautical / Space Industry

- Electronic

- Chemical, Pharmaceutical, Medical, Cosmetic, Food

Video

Robur parts washers are designed for washing processes where top-quality and the highest reliability are crucial.

Robur parts washers are equipped with an external trolley where parts are placed for washing.

Operators push then the platform with parts into the washing cabin, close the vertical door through a two-hand control system and start the working process.

A stainless steel vertical pump carries out the washing through the liquid intake from a tank and sprays it over the parts while a gear motor slowly turns the platform.

The parts washer can be entirely designed thanks to many accessories available and the whole working process is controlled by an industrial PLC.

On a colour touchscreen display can be changed the operating parameters such as the liquid temperature, the starting and switching off times, and checked the operation of each device installed as well as modified the 16 washing programs available.

Robur parts washers are extremely solid and with a long life cycle, thus ensuring better-than-expected results.

Washers are able to treat parts heavier than 4,000 kg thanks to a number of customizations such as the motorized platform and rotation of jets.

Available accessories: diesel or natural gas burner, high pressure pump, integrated manual washing, hot-air drying.

- Pneumatic opening and closing of the lid with 2 safety hands control

- Timed electric exhaustion of steam

- Aisi 304 stainless steel external trolley with drip tray and wheels with safety brake

- ISO pneumatic cylinders and “fall-proof” pneumatic safety valves

- Thermal tank insulation with Aisi 430 stainless steel panels

- Siemens® electric power parts

- 4” color touchscreen display for settings and programs

- Box filter made up of 6 Aisi 304 SS vertical filters for pre-filtration of the liquid flowing back into the tank

- Aisi 304 stainless steel filter in pump intake

- Triple gasket for door (bottom, top and side) and gaskets on all tank lids

- Structure and sheet metal in contact with liquid in Aisi 304 stainless steel

- Minimum level switch

- Pressure gauge for control of pressure delivered

- Safety limit switch on door opening

- Gearmotor for basket rotation with torque limiter and centering sensor

- Sludge drain hatch for simple tank cleaning

- Reinforced pressed grating platform with galvanized steel raised outer edge

- Multiple-stage vertical electric pump in Aisi 304 stainless steel with special seals

- Manually adjustable washing pressure

- Weekly programming to start heating and deoiler (if installed)

- IP65 electrical system, management via PLC touchscreen (DGT V4)

- Heating of the liquid with stainless steel electric heating element

- Internal welding bleaching

- Tanks accessible from the outside

- Stainless steel bottom section load-bearing structure

- Aisi 304 stainless steel washing pipelines with professional stainless steel flat nozzles

- Drain valves for emptying tanks

- Manual water filling valve

HT VERSION

- Heat insulation with Aisi 430 stainless steel panels

- Maximum liquid level control in tank 1 and filling solenoid valve

- Compressed air blowing

- Hot air drying with resistor and air blade side channel blower

- Demineralizer with mixed resins and conductivity meter

- Increased washing height

- Centrifugal steam condenser S

- Centrifugal steam condenser M

- Additional basket/platform

- Stainless steel Aisi 304 additional external trolley

- Automatic liquid detergent dispenser, installed in bath 1

- Disc oil separator with dedicated motorization

- External pneumatic oil separator

- Bag filter in stainless steel, installed in the bath 1

- Magnetic spark plug for bag filter for ferrite powder

- Device for remote connection and remote support for HMI Weintek

- Kit for Industry 4.0 for HMI Weintek

- Manual washing and blowing with hoses and washing nozzle

- 80 bar manual washing and blowing with hoses and washing nozzle (both for LT or for HT available)

- Motorised movement of the platform for loading and unloading [C]

- Kit for use with abrasive contaminants in the washing liquid

- Stainless steel fittings and valves kit ( for parts that are in contact with liquids)

- PLC Siemens® S7 1200 - HMI touchscreen Weintek

- High pressure washing pump

- Insulated stainless steel roller shutter front door

- Platform and spider in stainless steel Aisi 304

- External platform with hydraulic elevator

- Heating with natural gas / Diesel fuel burner

- Stainless steel Aisi 304 retention tank with drip-catcher

- Nebulized rinse from water mains, draining into the washing tank

- Compressed air blowing with upper pipe adjustable in height

- Tank on the opposite side when compared to standard

- Removable edges for grating in stainless steel, H 200 mm

- Emptying pump

- Signal tower for indicating system status

- Loading/ unloading external station ( second platform included)

ACCESSORIES NOTES LEGEND

C: the useful washing height is reduced by 130 mm