Parts washers catalog ROTOR LINE

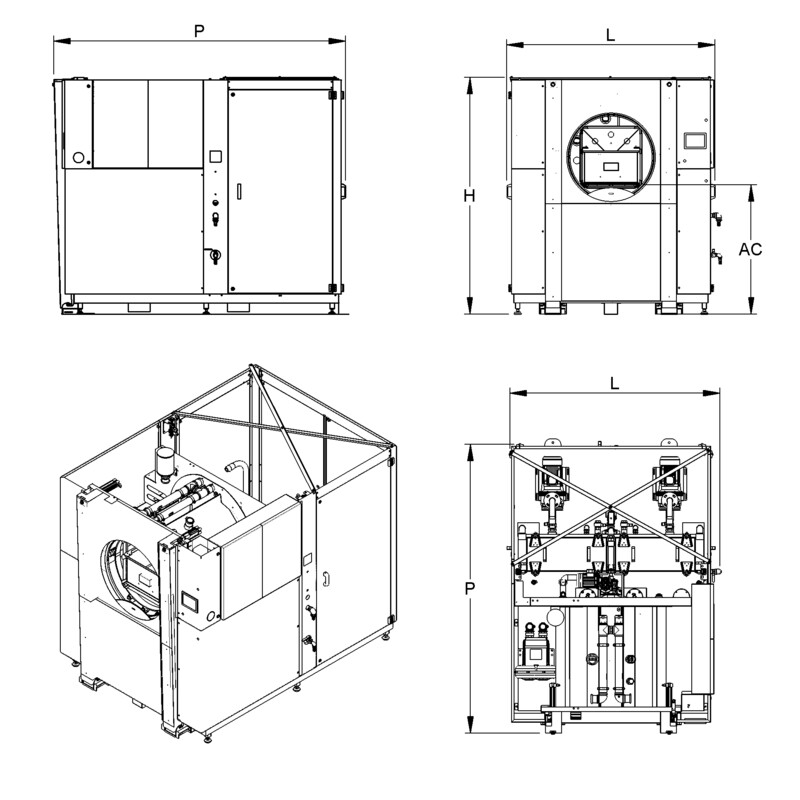

| Area di lavaggio | Portata di carico | Serbatoio | |

| XS | 22 x 37 cm | 30 Kg | 280 lt |

|---|---|---|---|

| S | 30 x 45 cm | 50 Kg | 500 lt |

| M | 50x 75 cm | 80 Kg | 900 lt |

| L | 75 x 100 cm | 100 Kg | 1400 lt |

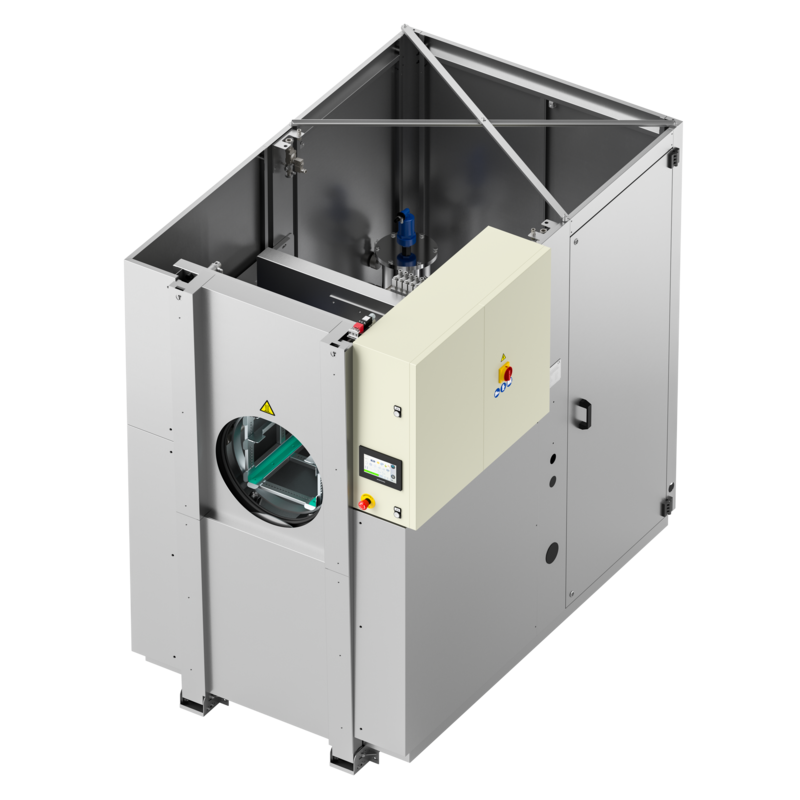

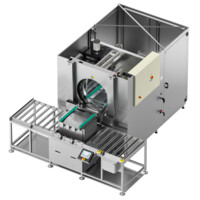

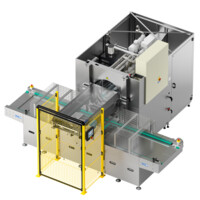

Automatic spray and hydrokinetic immersion parts washer with rotation on horizontal axis

Rotor is the optimal system for the spray and hydrokinetic immersion washing for baskets containing parts.

Basket is entered manually or automatically in the basket-holder drum according to the machine configuration.It is possible to set the basket rotation speed and the operation type: full or oscillating rotation.

Hot-air drying is included in the standard model. It is possible to increase it by a vacuum drying.

- HT (heating up to 80° C)

- PLC with color Touch Screen

- Industry 4.0 option

- Unique tank

- Mechanical engineering, chip removal, foundries, moulding

- Surface treatment, pre-painting, paint stripping

- Aeronautical / Space Industry

- Electronic

- Chemical, Pharmaceutical, Medical, Cosmetic, Food

Video

Rotor parts washers are used for small and medium-sized parts washing when the parts features and the washing requirements demand a washing immersed in full water.

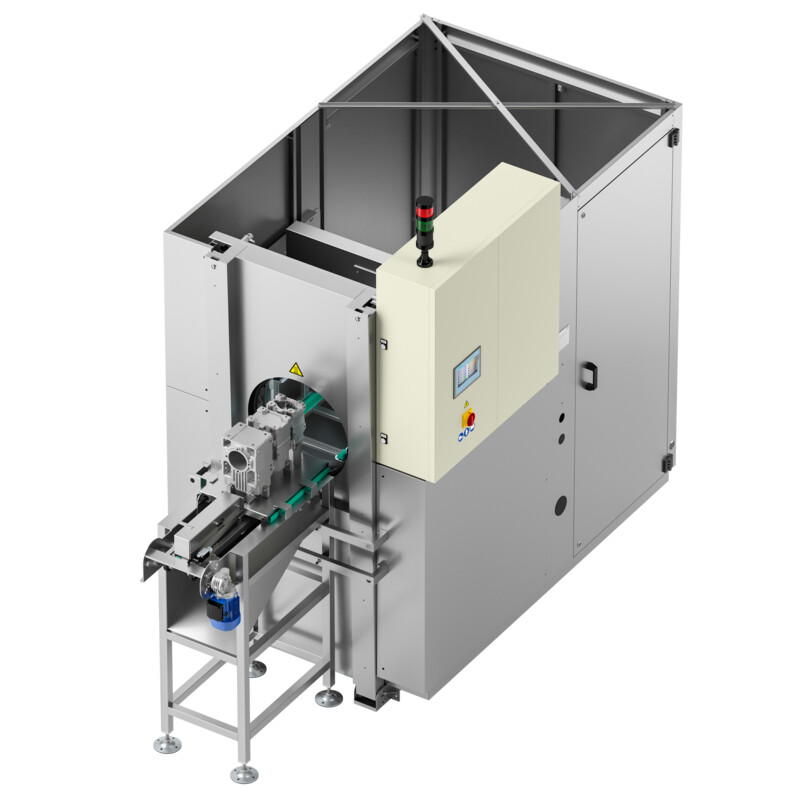

Parts are placed in a rectangular basket in stainless steel net that operators insert into the washing chamber where all treatment phases are performed. The automatic process starts after the watertight closing of the front pneumatic door.

A gear motor slowly turns the basket during the washing through a touchscreen switchboard that enables the speed and rotation mode settings: in continuous or tilting mode.

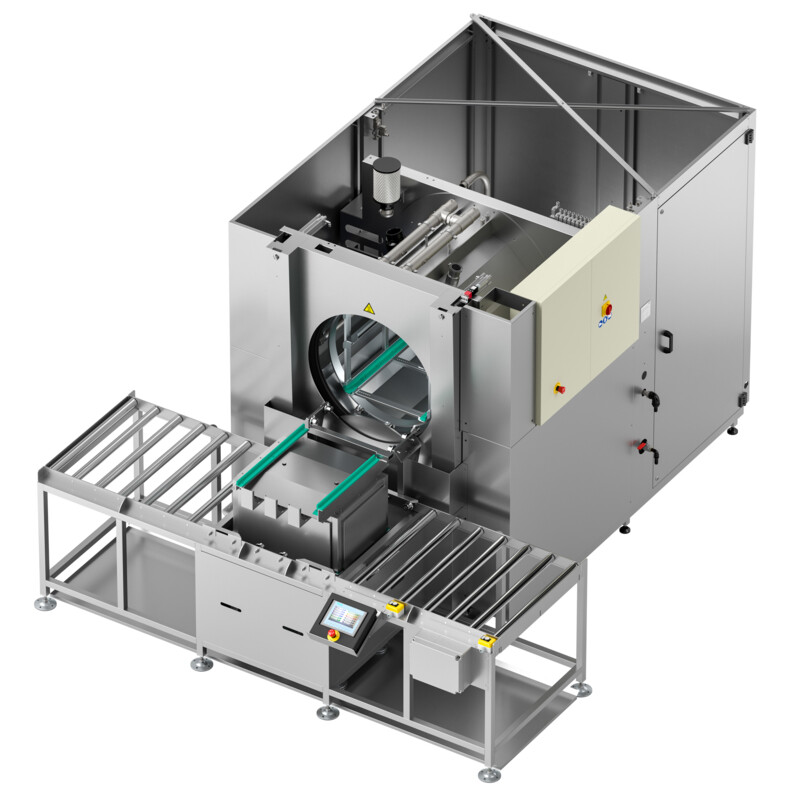

All working phases can be easily set in each of the 16 programs: spray washing, immersed in water washing, compressed air blowing, and hot drying.

The parts washer can be designed thanks to many accessories available in order to wash highly difficult parts: by intermediate or final rinsing cycles, and vacuum drying or by ultrasonic emitters for a better detergent effect.

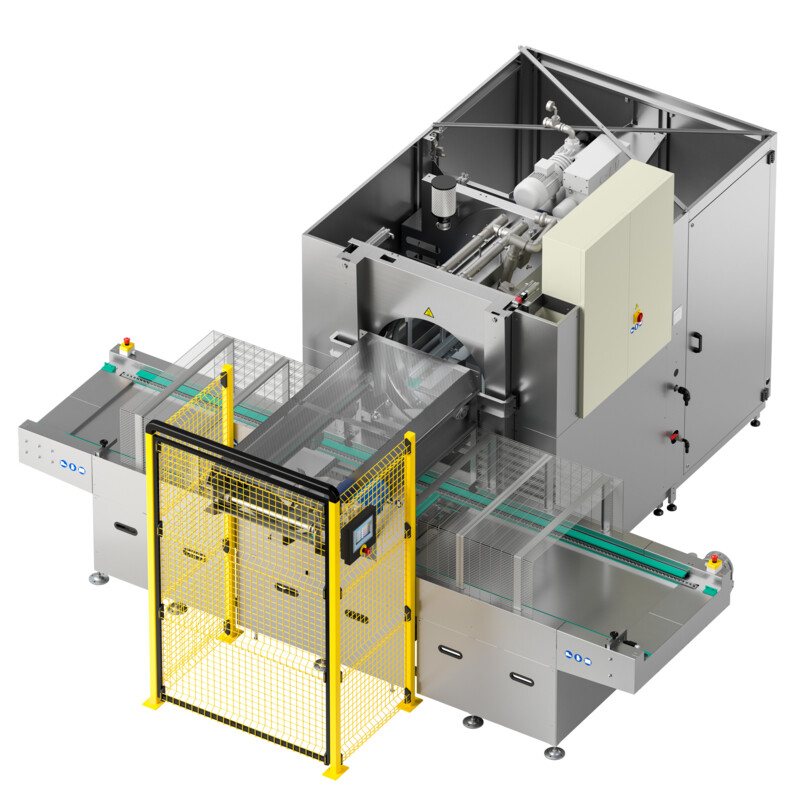

For a high productivity the machine can be supplied with a front roller conveyor for manual handling or automatic motorized loader of baskets. The Rotor versatility can make these parts washers an essential part in the robotic isles with parts loading and unloading directly from anthropomorphic robots.

- Rear Section machine total access through three doors (on the righthand side, lefthand side and at the back) in order to facilitate maintenance operations

- Pneumatic opening and closure of the hatch with 4 cylinders

- Hot air drying with side channel blower and heating elements

- ISO pneumatic cylinders and “fall-proof” pneumatic safety valves

- Siemens® electric power parts

- 7” color touchscreen display for settings and programs

- Box filter made up of 6 Aisi 304 SS vertical filters for pre-filtration of the liquid flowing back into the tank

- Aisi 304 stainless steel filter in pump intake

- Structure and sheet metal in contact with liquid in Aisi 304 stainless steel

- Minimum level switch

- Pressure gauge for control of pressure delivered

- Safety limit switch on door opening

- Gearmotor for variable basket rotation speed controlled by inverter

- Stainless steel electric pump with special seals

- Weekly programming to start heating and deoiler (if installed)

- IP65 electrical system, management via PLC touchscreen (DGT V4)

- Adjustment via software of the basket rocking limit angle, analogue reading of angulation 0/360°

- Heating of the liquid with stainless steel electric heating element

- Internal welding bleaching

- Compressed air blower solenoid valve

- Stainless steel bottom section load-bearing structure

- Aisi 304 stainless steel washing pipelines with professional stainless steel flat nozzles

- Drain valves for emptying tanks

- Manual water filling valve

- Aisi 304 stainless steel drip tray

- Maximum liquid level control in tank 1 and filling solenoid valve

- Demineralizer with mixed resins and conductivity meter

- Vacuum drying

- Loading/unloading area photocell barrier system

- Centrifugal steam condenser S

- Automatic liquid detergent dispenser, installed in bath 1

- External pneumatic oil separator

- Bag filter in stainless steel, installed in the bath 1

- Magnetic spark plug for bag filter for ferrite powder

- Device for remote connection and remote support for HMI Weintek

- Kit for Industry 4.0 for HMI Weintek

- Ultrasounds in titanium bars - 40 kHz

- Kit for use with abrasive contaminants in the washing liquid

- Stainless steel fittings and valves kit ( for parts that are in contact with liquids)

- PLC Siemens® S7 1200 - HMI touchscreen Weintek

- High pressure washing pump

- Interface with the loading and unloading system (robot)

- Rinsing by water supply and direct drain outlet

- Nebulized rinse from water mains, draining into the washing tank

- Emptying pump

- Signal tower for indicating system status

- A wide choice of external conveyors, with or without lift

- Single external station with automatic loading and unloading of baskets/pallets

- Automatic external roller conveyor pneumatic lift pos. 3+1+3

- Box covering application during automatic loading [E]

- Manual box tilter for emptying pieces at the end of the roller conveyor

- Increased loading capacity

- Stainless steel baskets in multiple sizes to choose

- Special drum for pallet support with anti-tilt system

- Workpieces positioning /clamping pallet

ACCESSORIES NOTES LEGEND

E: available only in case of automatic loading system of the baskets.