Parts washers catalog P LINE

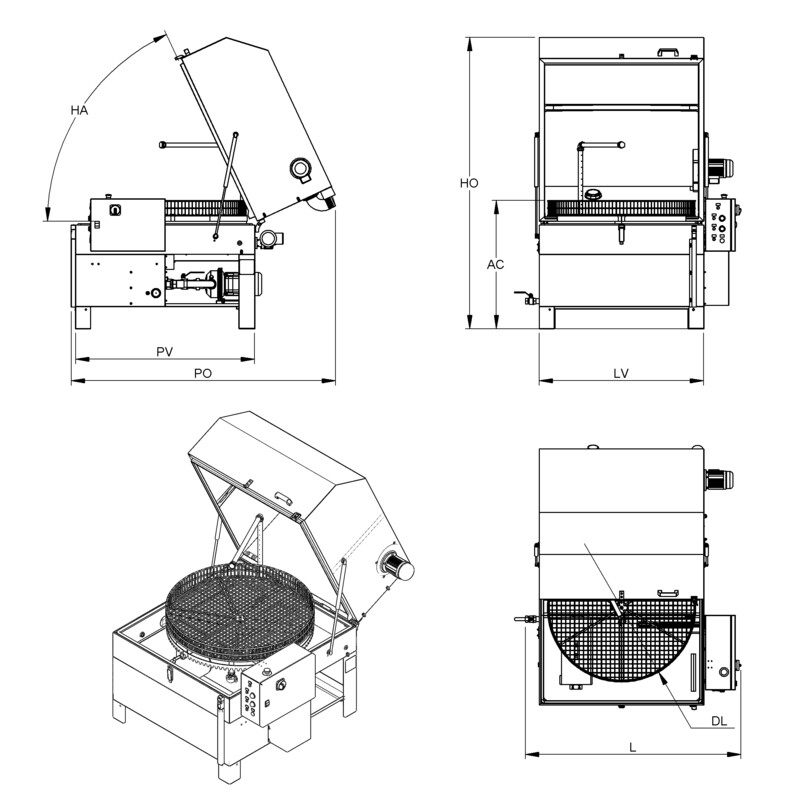

| Washing capacity ( Ø x H ) | Basket load capacity | Tank | |

| P 100 | Ø 95 x H 54 cm | 200 kg | 210 lt |

|---|---|---|---|

| P 120 | Ø 117 x H 70 cm | 300Kg | 270 lt |

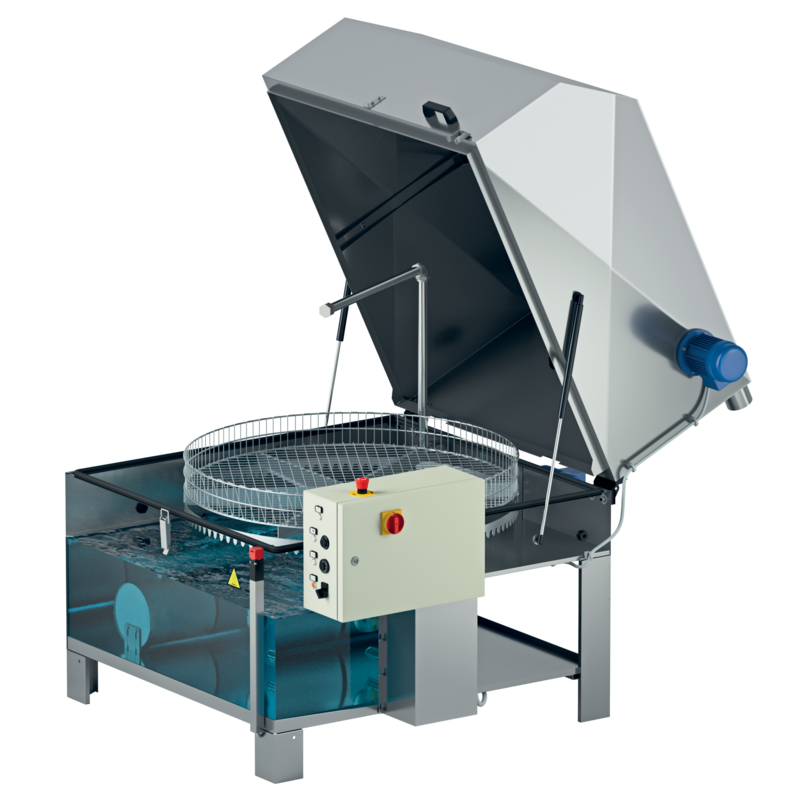

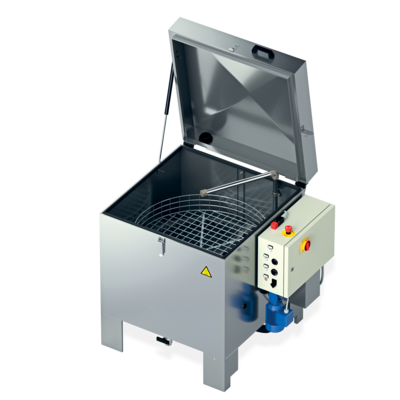

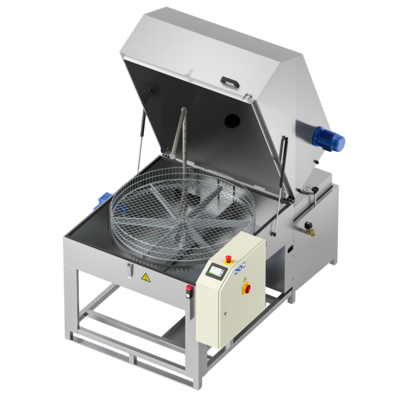

Parts washers with rotary basket and electromechanical commands

P is the optimal system for the automatic washing of medium size mechanical parts.

Washing is carried out by the action of upper, lower and side nozzles.

Basket rotates through a gear motor. The switchboard is electromechanical. Operators can set the tank liquid temperature as well as the length of the treatment cycle.

- LT (heating up to 60° C)

- Electromechanical

- Unique tank

- Car/motorcycle maintenance

- Truck maintenance

- Mechanical engineering, chip removal, foundries, moulding

Video

P100 and P120 parts washers for the automatic medium-sized parts washing.

Operators allocate parts inside the basket, close the cover and start the cycle.

Fully automated process - no operator needed.

A gear motors slowly turns the basket and the pump sprays the detergent liquid with pressure over the parts from the higher, lower and side pipes.

The washing liquid is made up of eco-friendly soaps mixed in water by a low-percentage.

On the switchboard can be set the liquid heating (max 60 °C) through a manual thermostat, and the washing time (0 to 30 minutes) through a timer.

Stainless-steel AISI 304 structure, pump and washing pipes.

P100 and P120 parts washers are equipped with standard motorized steam extraction to avoid operators being damaged from an excessive quantity of steam.

- Timed electric exhaustion of steam

- Reinforced basket in electrically welded mesh with external border in galvanized steel

- Hatch closure assisted with gas springs and fastening hook

- Aisi 304 stainless steel filter in pump intake

- Tank border gasket

- Structure and sheet metal in contact with liquid in Aisi 304 stainless steel

- Minimum level switch

- Safety limit switch on cover opening

- Stainless steel electric pump with special seals

- IP65 electrical system, electromechanical controls

- Heating of the liquid with stainless steel electric heating element

- Mechanical rotation of basket via gearmotor

- Internal welding bleaching

- Aisi 304 stainless steel washing pipelines with professional stainless steel flat nozzles

- Drain valves for emptying tanks

- Manual water filling valve

- Compressed air blowing (fixed time 3') [B]

- Basket in stainless steel Aisi 304

- Disc oil separator with dedicated motorization

- Kit for use with abrasive contaminants in the washing liquid

- Stainless steel fittings and valves kit ( for parts that are in contact with liquids)

- High pressure washing pump

- Panels under the basket with cap filter for collecting grease and chips

- Upper ramp fastened to the cover

- Machine equipped with wheels for handling

- Emptying pump

ACCESSORIES NOTES LEGEND

B: panels under the basket are mandatory (if in the price list for that model)