Teknox metal cleaning machines: innovation and precision serving the aerospace industry

The aerospace sector is distinguished by the need to ensure the highest cleaning standards at every stage of production and maintenance. Teknox meets these demands by offering advanced metal washing machines, designed to solve the typical challenges of this industrial field, such as the removal of invisible contaminants and the cleaning of components with complex geometries.

The main challenges in aerospace cleaning

- Removal of invisible contaminants: During manufacturing processes such as turning, milling, or surface treatments, metallic components can accumulate contaminants invisible to the naked eye, including oils, greases, powders, or abrasive residues. If not properly removed, these contaminants can compromise the quality of welds, adhesion of coatings, or the reliability of propulsion systems.

- Cleaning of complex geometries: Many aerospace components have intricate geometries with deep cavities, microholes, or internal surfaces that are difficult to reach. Traditional washing technologies may be ineffective in ensuring uniform and thorough cleaning.

- Sensitive materials and delicate surfaces: Aerospace components often include lightweight alloys or composite materials that require delicate cleaning treatments to avoid surface damage.

- Efficiency in time and cost: The need to optimize production and maintenance cycles makes the adoption of fast and efficient metal washing machines essential, without compromising cleaning quality.

Teknox solutions for the aerospace sector

Teknox develops metal cleaning machines that integrate innovative technologies to successfully address these challenges. Among our main solutions:

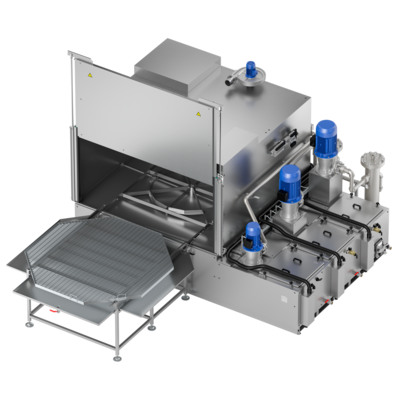

- Spray washing: Ideal for removing surface contaminants from large or regularly shaped parts, ensuring fast and effective cleaning. (Model Robur 1B, 2B)

- Hydrokinetic immersion washing: Ideal for removing surface contaminants from parts with complex shapes and geometries, ensuring deep and effective cleaning. (Model Rotor 1B, 2B, 3B)

- Ultrasonic washing: The optimal solution for complex or sensitive components, such as parts with internal cavities or microholes, thanks to the deep and uniform action of cavitation. (Model Series K)

Each Teknox machine can be configured with customized washing cycles and the most suitable detergents based on the type of application, ensuring environmental sustainability and high operational efficiency.